Exposure Machine

Fully automatic exposure machine

Exposure light source:

● Exposure source: mercury lamp 350W, 500W, 1000W, or UV LED.

● Exposure light source aperture: 4", 6", 8", 10", 12" round, or 4", 6", 8" square ● Wavelength: Mercury lamp NUV (365nm, 405nm, 435nm), UV LED (365nm, 405nm)

● Light source parallel half angle: 1.5~2.5 degrees (depending on the light outlet diameter)

● Uniformity: +-3~5% (optional +-2%)

● Comes with high-pressure mercury lamp, or UV LED lamp set and power supply (optional feedback type)

Automatic alignment stage:

● Mask vacuum suction cup: Upward suction or downward suction 4", 5", 6", 9"

● Wafer vacuum chuck: 2", 4", 6", 7", 9”

● With mask wafer level correction function ● Exposure mode can be selected as contact type and proximity type,

● X, Y, T axis motor adjustment 10mm. Resolution 1um

● Z-axis motor adjustment 5mm, resolution 1um

● The mask is transferred forward and backward for easy placement. ● The automatic alignment action is adjusted by PLC control according to the calculation results of the automatic alignment software.

Imaging system:

Uses a fixed magnification lens, configured in three positions: pre-alignment, rough alignment for film advance, and precision alignment

The CCD imaging system captures images to the PC for automatic image alignment.

Image lighting includes LED coaxial light or ring light

Pre-transfer table:

The film is sent to the pre-alignment stage by the small arm for rough positioning, and after exposure, it is sent to the transfer stage for film output by the small arm

Transmitting small arm and turntable:

5 small arms for wafer transfer, three suction cup turntable combined with alignment table for fast alignment and wafer loading and unloading

Input and output cassette station:

The input cassette station uses an arm to transfer the substrate to the pre-alignment station. After exposure, the substrate is transferred from the transfer station to the wafer boat of the output cassette station. The unfinished substrate is basically moved to the unloading station. The cassette station can be designed with multiple cassettes.

Operating System:

PLC and human-machine interface control system and industrial computer automatic alignment software for substrate input and output and automatic alignment exposure program operation.

Base:

It has four anti-vibration air cushions, adjustable feet, moving wheels, aluminum extrusion frame with aluminum plate and yellow PVC anti-static sheet covering the machine, and several operation and maintenance doors and windows.

Transmitting small arm and turntable:

5 small arms for wafer transfer, three suction cup turntable combined with alignment table for fast alignment and wafer loading and unloading

performance:

The output varies depending on the alignment accuracy and exposure time. The high-output model can reach more than 5 pieces per minute.

The best resolution of contact exposure pattern can reach 1~2um

Proximity exposure is used, and the distance between the wafer and the mask is set at about 5~2um.

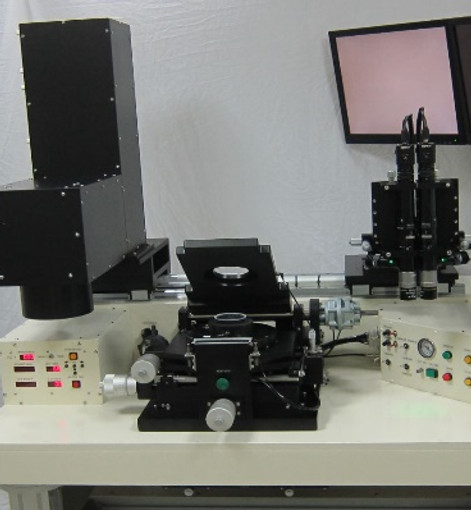

Semi-automatic exposure machine

Semi-automatic mask alignment exposure machine is easy to operate, reliable in performance, and suitable for mass production lines

Exposure light source:

● Exposure source: Mercury lamp 350W, 500W, 1000W, or UV LED lamp

● Exposure light source size: 4", 6", 8", 10", 12" round, or 4", 6", 8" square ● Wavelength: Mercury lamp NUV (365nm, 405nm, 435nm), UV LED (365nm, 405nm)

● Light source parallel half angle: 1.5~2.5 degrees, (depending on the light outlet diameter)

● Uniformity: +-3~5% (optional +-2%)

● Comes with high-pressure mercury lamp, or UV LED lamp set and power supply (optional feedback type)

Exposure alignment station:

● Mask vacuum suction cup: Upward suction or downward suction 4", 5", 6", 7", 9"

● Wafer vacuum chuck: 2", 4", 6", 8" round or square ● With mask wafer parallel correction function ● Exposure modes include vacuum contact, soft contact and proximity, and the vacuum adsorption force can be adjusted ● X, Y, T axis manual adjustment stroke 10mm. Adjustment resolution 1um

● Z-axis manual adjustment stroke 3mm, micrometer resolution 1um, (electric adjustment optional)

● The mask chuck automatically opens to pick up and place the substrate

Imaging system:

The variable magnification lens is used to facilitate the alignment operation, with a standard magnification of 50X-300X.

Optional multiple magnifications, CCD imaging system, LCD screen display

LED coaxial lighting, (optional ring light)

The distance between two observation points is 4cm-15cm, (optional folding mirror can be used to achieve a smaller distance)

Optional lens scanning platform can quickly move the lens,

Optional backside alignment imaging system

Base:

It has four shockproof air cushions, adjustable feet, moving wheels, frame and plate, large aluminum plate base, linear slide rails for left and right movement, CDA adjustment, power input and output, etc.

Operating System:

PLC semi-automatic operating system, (optional human-machine interface).

The operation process can be switched between manual and semi-automatic modes: place the substrate, (press the button) close the upper mask, move the lens in for alignment, (press the button) select the exposure mode, (press the button) move the lens out and the light source in for exposure, move the light source out, open the mask suction cup, and take the substrate.

Exposure shutter control: timer control 0.1-999 seconds, (optional energy control: 0.1~9000mJ/cm2).

performance:

The output varies depending on the alignment accuracy, exposure time and operator proficiency. The fastest can reach three pieces per minute. The best pattern resolution can reach 1um (positive photoresist thickness 1um) with vacuum contact exposure. The best resolution is about 2~5um with proximity exposure.

Double-sided alignment exposure machine

Exposure light source:

● Exposure source: mercury lamp 350W, 500W, 1000W, or UV LED.

● Exposure light source aperture: 4", 6", 8", 10", 12" round, or 4", 6", 8" square ● Wavelength: Mercury lamp NUV (350nm~450nm), UV LED (365nm, 405nm)

● Light source parallel half angle: 1.5~2.5 degrees (depending on the light outlet diameter)

● Uniformity: +-3%

● Comes with high-pressure mercury lamp, or UV LED lamp set and power supply (optional feedback type)

Double-sided alignment table:

● Mask vacuum chuck: 4”, 5”, 7”, 9”

● Wafer vacuum chuck: 2”, 3”, 4”, 6” 8”

● Wafer vacuum chuck has holes for back-to-back alignment.

● With mask wafer parallel surface correction function ● Exposure modes include vacuum contact, contact and proximity,

● X, Y axis adjustment stroke: 12mm. Adjustment resolution 1um.

● Rotation axis adjustment angle: 5 degrees, adjustment resolution 0.001 degrees,

● Z-axis adjustment stroke: 3mm, adjustment resolution 1um. Micrometer display.

● Wafer placement can be done by wafer push-pull tray or mask top opening.

Upper alignment imaging system:

Adopt variable magnification lens, various magnification combinations, dual CCD imaging system, LCD screen

LED coaxial lighting or annular lighting lens can be fine-tuned by about 20mm in front, back, left, right, up and down directions.

Optional fast scanning station,

The best image resolution can reach 1um.

Back-aligned imaging system:

Can use fixed magnification lens dual CCD imaging system, switch to use upper image LCD screen

LED coaxial lighting, back-alignment, image processing software, lens fine-tuning of about 10mm in front, back, left, right, up and down directions,

The best image resolution can reach 1um.

Operating System:

PLC semi-automatic operating system, (optional human-machine interface).

The operation process can be switched between manual and semi-automatic modes: place the substrate, (press the button) close the upper mask, move the lens in for alignment, (press the button) select the exposure mode, (press the button) move the lens out and the light source in for exposure, move the light source out, open the mask suction cup, and take the substrate.

Exposure shutter control: timer control 0.1-999 seconds, (optional energy control: 0.1~9000mJ/cm2).

Shockproof base:

The large aluminum base is equipped with four shockproof air cushions, the frame has adjustable feet, moving wheels, CDA input adjustment, vacuum input, power input and output.

Double-sided exposure machine

Semi-automatic double-sided exposure machine, easy to operate, reliable performance, double the capacity, suitable for mass production line use

Upper and lower exposure light source:

● Exposure source: Mercury lamp 350W, 500W, 1000W, or UV LED

● Light exposure source size: 4", 6", 8", 10", 12" round, or 4", 6", 8" square ● Wavelength: Mercury lamp NUV (365nm, 405nm, 435nm), UV LED (365nm, 405nm)

● Light source parallel half angle: 1.5~2.5 degrees (depending on the light outlet diameter)

● Uniformity: +-3~5% (optional +-2%)

● Comes with high-pressure mercury lamp, or UV LED lamp set and power supply (optional feedback type)

Double-sided exposure alignment station:

● Upper and lower mask vacuum chucks: 4", 5", 6", 7", 9"

● Base plate clamp: 2", 4", 6", 8"

● The lower mask can be manually adjusted to be parallel to the upper mask. ● The exposure mode is contact type. ● Mask to mask alignment: X, Y, Y axis adjustment 10mm. Fine thread screw adjustment

● Alignment of the photomask to the substrate: XYθ adjustment 10mm, micrometer adjustment

● The upper mask is opened to place the substrate, and the substrate is fixed diagonally between the two masks with a fixing clamp

Imaging system:

The variable magnification lens is used to facilitate the alignment operation, with a standard magnification of 50X-300X.

CCD imaging system, 2 LCD screens with LED coaxial lighting, backlight or ring light. A lens scanning stage can be installed to quickly move the lens.

A mask monitoring lens can be installed to monitor the upper and lower mask displacement.

Base:

It has four shockproof air cushions, adjustable feet, moving wheels, stainless steel bracket and plate, aluminum alloy table and ribs, CDA adjustment, vacuum display, power input and output, etc.

Operating System:

Adopt PLC semi-automatic operating system,

Can switch between manual and automatic modes Operation process: Place substrate, (press button) upper mask close, lens moves in for alignment, (press button) upper mask presses down, lens moves out and light source moves in for exposure

(Time), remove the light source, open the photomask, and take out the substrate.

Exposure timer setting: 0.1-999 seconds

performance:

The output varies depending on the alignment accuracy, exposure time and operator proficiency, and can reach up to three pieces per minute.

Fully manual mask exposure machine

The fully manual mask alignment exposure machine is suitable for laboratory research or process development before mass production.

Exposure light source:

● Exposure source: mercury lamp 350W, 500W, 1000W, or UV LED lamp ● Exposure light source size: 4", 6", 8", 10", 12", round or square,

● Wavelength: Mercury lamp NUV (350nm~450nm), UV LED (365nm, 405nm, 435nm)

● Light source parallel half angle: 1.5~2.5 degrees (depending on the light outlet diameter)

● Uniformity: +-3~5%

● Comes with high pressure mercury lamp, or UV LED lamp set and power supply

Exposure platform:

● Mask vacuum suction cup: Upward suction or downward suction 4", 5", 6", 7", 9"

● Wafer vacuum chuck: 2", 4", 5", 6", 8", round or square,

● With mask wafer level correction function ● Exposure modes include vacuum contact and proximity, and the vacuum adsorption force can be adjusted ● X, Y axis adjustment 10mm. The best adjustment sensitivity is 1um

● Z axis can be adjusted 3mm, micrometer resolution 1um

● The photomask is opened by hand to take and place the substrate

Imaging system:

Variable magnification lens, screen magnification about 80X-500X,

The best image resolution is 1.5um

Video camera, LCD screen lighting with LED coaxial light or ring light observation of two points distance 4cm-15cm, (optional folding mirror to a smaller distance)

Choose a lens scanning stage to quickly move the lens.

Choose rear-side alignment model

Base:

Large aluminum plate machine base, stainless steel bracket, with four shockproof air cushions, adjustable feet, moving wheels, CDA input adjustment, vacuum input, power input and output, etc.

Operating System:

Fully manual operation system, every action needs to be manually operated.

Operation process: Place the substrate, manually close the mask suction cup, move the lens in for alignment, move the chuck up to the exposure position, move the lens out and move the light source in for exposure (timing), move the light source out, open the mask suction cup, and take out the substrate.

Exposure timer setting: 0.1-999 seconds optional energy exposure

performance:

The best resolution of vacuum contact exposure pattern can reach within 1um (positive photoresist thickness 1um)

Proximity exposure is used, and the best distance between the wafer and the mask is set to about 5~2um

Desktop Alignment Exposure Machine

Exposure light source:

● Exposure source: Mercury lamp 350W or 500W, or UV LED lamp ● Exposure light source size: :4", 5", 6" or 8"

● Wavelength range: NUV, I-line Intensity: about 10~25mW/cm2@6”

● Uniformity: within +-5%, Parallel angle: ±2.5°

● One power supply ● One exposure control timer: 0.1~999.9 seconds ● One high-pressure mercury lamp or one UV LED lamp set

Exposure alignment station:

● Mask vacuum chuck: 4”, 5" or 6” downward suction type ● Wafer vacuum chuck: broken piece, 2”, 3" , 4" or 5”

● With vacuum ball seat for parallel calibration between mask and wafer ● Wafer vacuum chuck can be adjusted 12mm forward, backward, left and right, with adjustment sensitivity of 2um

● Rotation adjustment 5 degrees, adjustment sensitivity 0.001 degrees ● Z axis can be adjusted about 3mm, adjustment sensitivity 1um.

● Z-axis micrometer can display the distance between the mask and the wafer, with a resolution of 1um

Z axis can be set to two gaps: alignment and exposure

Adjustable contact vacuum force

Exposure modes include Vacuum contact, Soft contact, Proximity

Manually place the chip and adjust the chip position. When placing and removing the wafer, the mask suction cup is opened by hand.

Imaging system:

One set of variable magnification lens, video camera, LCD screen, LED light source, or two sets of imaging system with a total imaging magnification of 50X-300X.

The best image resolution is 1.5um

The lens position can be adjusted by about 20mm in the front, back, left, right, up and down directions.

Single lens with fast scanning platform, can quickly move the lens, forward and backward, left and right movement of about 10cm

Base:

Desktop large base stand with adjustable feet

Operating System:

The system is operated by manual dial knobs. The operation items include the replacement of the mask and wafer, the switching of the gap between the mask and wafer, the parallelism calibration of the mask and wafer, the switching of vacuum contact and the adjustment of vacuum value.

The Z-axis scale is reset to zero, and the lens and exposure source are moved alternately left and right to the top of the alignment stage, with a safety interlock function.

performance:

The best resolution of vacuum contact exposure pattern can reach 1um, and the best resolution of proximity exposure pattern can reach 5~2um according to the gap between the mask and the wafer.

Simple manual exposure machine

Exposure light source:

● Exposure source: mercury lamp 350W, 500W, 1000W, or UV LED lamp ● Exposure light source size: 4", 6", 8", 10", 12", round or square,

● Wavelength: Mercury lamp NUV (350nm~450nm), UV LED (365nm, 405nm, 435nm)

● Light source parallel half angle: 1.5~2.5 degrees (depending on the light outlet diameter)

● Uniformity: +-3~5%

● Comes with high pressure mercury lamp, or UV LED lamp set and power supply

Exposure platform:

● Mask vacuum chuck: 4”, 5”, 6”, 7”, 9” (optional)

● Wafer or substrate vacuum chuck: 2”, 4”, 5”, 6”, 8”, 12” (optional)

● With the function of parallel correction between the mask and the wafer or substrate ● The Z axis can be manually adjusted by about 3mm, with an adjustment resolution of 1um.

● Z-axis micrometer can display the distance between the mask and the wafer ● Exposure modes include Vacuum contact, Soft contact, Proximity

● Manually place the chip or substrate and adjust the chip position. When placing and removing the wafer, the mask suction cup opens upwards.

Imaging system:

without

Base:

Large aluminum plate machine base, stainless steel frame, four shockproof air cushions, adjustable feet, moving wheels, CDA input adjustment, vacuum input, power input and output, etc.

Operating System:

The system is operated by manual dial knobs. The operation items include the replacement of the mask and wafer, the switching of the gap between the mask and wafer, the parallelism calibration of the mask and wafer, the switching of vacuum contact and the adjustment of vacuum value, the zeroing of the Z axis, the left and right movement of the exposure source to the top of the alignment stage,

Shutter controller: timing control,: 0.1~999.9 seconds,

Energy control: 0.1~9999.9mJ/cm2 (option).

performance:

If contact exposure is used, the I-line photoresist thickness is 1um, and the best pattern resolution can reach 1um.

The line width of close exposure can reach 5~2um according to the gap setting.